Corporate Profile

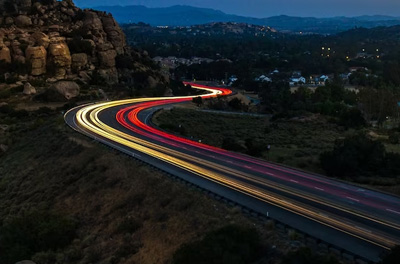

Shaping India’s

tomorrow

Leveraging our vast industry experience and know-how, we are poised to support India's growth journey in the foreseeable future.

Introduction

Shiva Cement is a well-positioned player in the cement value chain and is presently a part of the prestigious JSW Group. Having started our operations in Odisha in 1985, we are today expanding our capacities to cater to the emerging opportunities in the eastern India markets. We are enabled by robust raw material reserves, proximity to the market, and a strong focus on sustainable growth.

This 1 MTPA Grinding capacity has been achieved through an exclusive manufacturing partnership with our group company Bhushan Power and Steel Limited.

1985

Year of Inception

1 MTPA

Grinding Capacity

1.5 MTPA

Clinker Production Capacity

Key advantages

Our long-standing success and history have allowed us to build a strong organisation with various competitive advantages. We have consolidated our footprint, improved cost efficiency and resource management, and strengthened our supply chain networks over time by implementing best-in-class procedures and practices. We have looked at expanding our operations further, using the experience of our parent firm, JSW Cement. Our manufacturing facility is strategically located at the geographical border of three eastern states of India, namely Odisha, Chhattisgarh, and Jharkhand, having proximity to the raw materials that we require for our operations, including limestone, clay, laterite, iron fines, slag, gypsum, and fly ash. It is also well-connected to our key markets by road and railways. We believe that this shall enable our manufacturing facility to act as a feeder to the eastern plants of JSW Cement, providing us with a competitive advantage.

In addition, our facility is 2 km from the state highway connecting Rourkela and Jharsuguda. The nearest railway stations are located at Sagra and Sonakhan, which are about 24.00 km and 19.00 km, respectively, from our manufacturing facility by road, making transportation cost-effective and time-efficient simultaneously.

We are ideally located, with quick access to critical raw materials and the ability to reach markets at a low cost. Additionally, our production facilities are near key markets.

Our leadership team comprises individuals with a wide range of expertise. Their extensive experience in the cement business gives valuable insight into the Company’s future development and expansion plans.

As part of JSW Group, we supply clinker to JSW Cement Limited with a view to increasing the efficiency and productivity of the JSW Group. Our Expansion Project is a strategic initiative aimed at to enabling the supply of clinker to JSW Cement Limited since the cost of imported clinker is high in the eastern region of India and the domestically sourced clinker from the Nandyal unit of JSW Cement Limited is significantly higher. The strategic location of our manufacturing facility enables us to also act as a clinker feeder to JSW Group’s eastern plants at Salboni in West Bengal and Jajpur in Odisha.

Further, the JSW Group recently acquired Bhushan Power & Steel Limited, which has its steel manufacturing plant located in Jharsuguda, Odisha, within a radius of 80-100 km from our manufacturing facility, providing us with the ability to source cost-efficient input raw materials such as slag and fly ash.

Shiva Cement will produce a total of 1.5 million tonnes of clinker. Following the conclusion of the project, we will look for new ways to expand. The whole complex will ultimately generate up to 3 million tonnes of clinker, which is comparable to 10 million tonnes of slag cement, in India’s eastern area.

To safeguard the well-being of our employees and workers, we adhere to JSW Cements’ health and safety policy and conduct various seminars, training, and promotional activities. Our promotional campaigns and on-site recognition events inform and inspire our employees on health and safety. To guarantee the safety of our personnel, we scheduled safety action meetings for off-site incidents at the fabrication yard and mock safety drills at mines on a quarterly basis.

We believe that an appropriate information technology infrastructure is important to in order to support the growth of our business. We have implemented an integrated business management software for the planning and management of operations at our manufacturing facility, including an integrated SAP enterprise resource planning solution covering sales, production planning, material management, quality control, finance and accounting, plant maintenance, and human resources. We believe such systems and processes enable us to manage our operational efficiency, quality, and customer service, along with incorporating necessary controls and checks and balances in the business operations. Our IT infrastructure also enables us to generate the reports and information required to assist our management in decision-making.

Vision

We, at Shiva Cement, share a vision to emerge as an innovative, cost-efficient, and socially responsible organisation to augment our growth along with that of our stakeholders and serve the nation.

Shiva Cement is a strategic investment to make its parent company, JSW Cement a 10 MTPA (Million Tonne Per Annum) player in the eastern part of the country and a 25 MTPA player across India. With a state-of-the-art setup for manufacturing sustainable products, we endeavour to support India’s growth as an industrially advanced nation.

Project Partners

TKIL

TKIL is one of the world's leading engineering firms Specialising in plant and equipment for the cement and mineral processing industry. TKIL plant and equipment with a brand name “POLYSIUS” are at the forefront of the technology.

TKIL supported us in designing and engineering and supplied us with world-class power-efficient, sustainable, and robust equipment's as follows:

- Raw mill : Polysius compressive mill (POLYCOM) 340 TPH

- Coal Mill : QUADROPOL QMK2 32/16

- Pyro Section : Preheater- DOPOL 90, V stage; Kiln with flair design of 4.6/4.2 meter diameter & 64 meter length and POLYTRACK 8T-5-0-3R-B cooler.

ABB

ABB is a technology leader in electrification and automation and provides integrated products, services and solutions to customers in the cement industry to optimise their power and productivity, resulting in efficient production.

ABB supplied us :

- DCS 800XA ABILITY 6.0

- MV LV Switch gear

FLS

FLS is the world’s best technology provider to cement industries. FLS has supplied us:

- RoboLab (QCX-30) – is a high-tech robotics solution for automated sample preparation, analysis, and automated quality assurance (QA) and quality control (QC) procedures. This advanced automation system ensures most accurate, and speedy analysis.

L&T

- L&T is India biggest conglomerate, having expertise in construction, engineering, and manufacturing

- It has supported us in execution (civil and mechanical) of our 4000 TPD clinkerisation plant

Our footprint

Breaking barriers.

Building strength.

Our goal going forward is to leverage our strengths and devise well-sought out expansion strategies that would enable our organisation, to cement its position as the market leader in eastern India.